Turbine Configurations

Steam Turbine Configurations based on Steam Usage

Turtle Turbines manufactures variety of steam turbines in various configurations to meet industrial heat and power requirements.

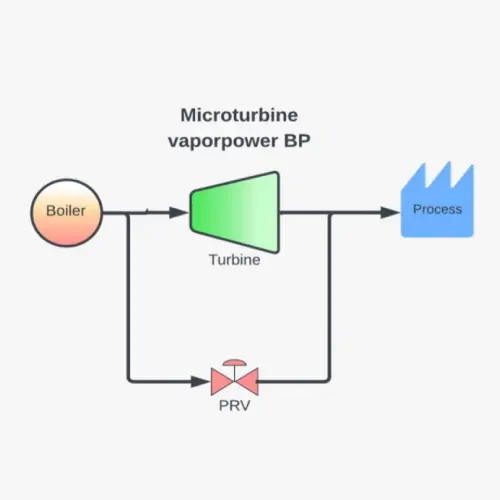

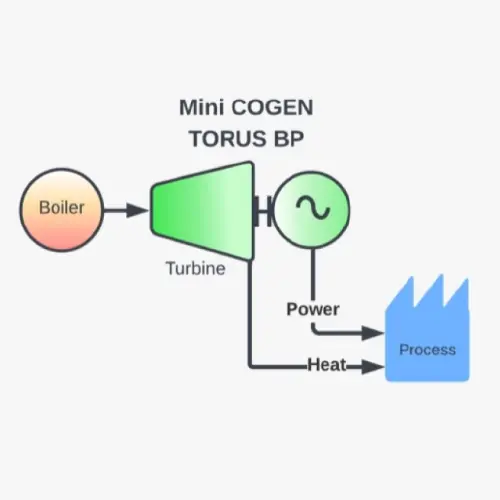

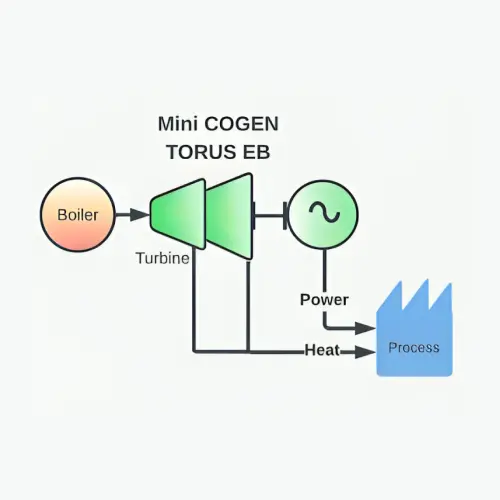

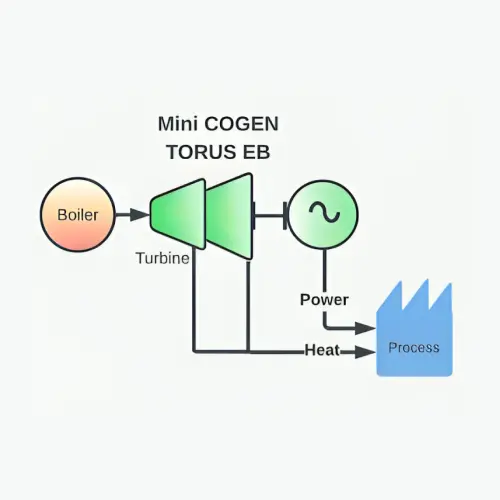

Back Pressure Steam Turbines

Back pressure steam turbines are used for power generation in industrial processes. They expand high-pressure steam to lower pressure, often to meet specific industrial needs and at the same time generate electricity. Back Pressure Steam Turbines are commonly used in Cogeneration systems to maximise energy efficiency.

Maximise Effificency

Back Pressure Steam Turbines maximise energy efficiency of the process plants

Reduce Cost

Back Pressure Steam Turbines drastically reduce Energy Cost thus reducing production cost

Steam Turbine Configurations based on Steam Usage

Turtle Turbines manufactures variety of steam turbines in various configurations to meet industrial heat and power requirements.

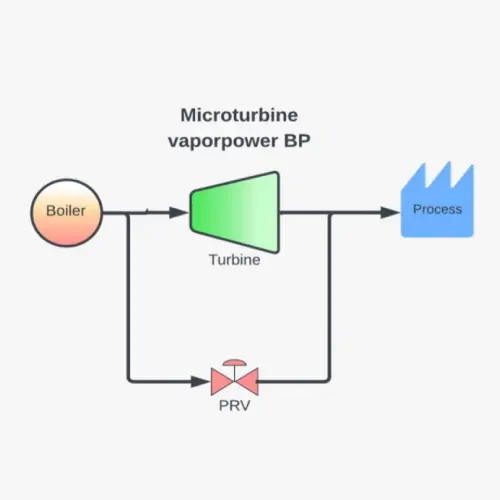

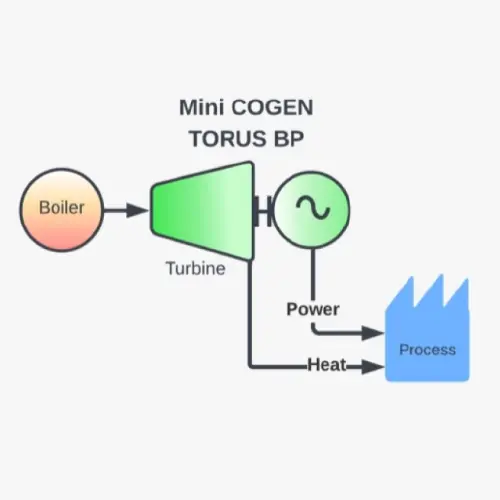

Back Pressure Steam Turbines

Back pressure steam turbines are used for power generation in industrial processes. They expand high-pressure steam to lower pressure, often to meet specific industrial needs and at the same time generate electricity. Back Pressure Steam Turbines are commonly used in Cogeneration systems to maximise energy efficiency.

Maximise Effificency

Back Pressure Steam Turbines maximise energy efficiency of the process plants

Reduce Cost

Back Pressure Steam Turbines drastically reduce Energy Cost thus reducing production cost

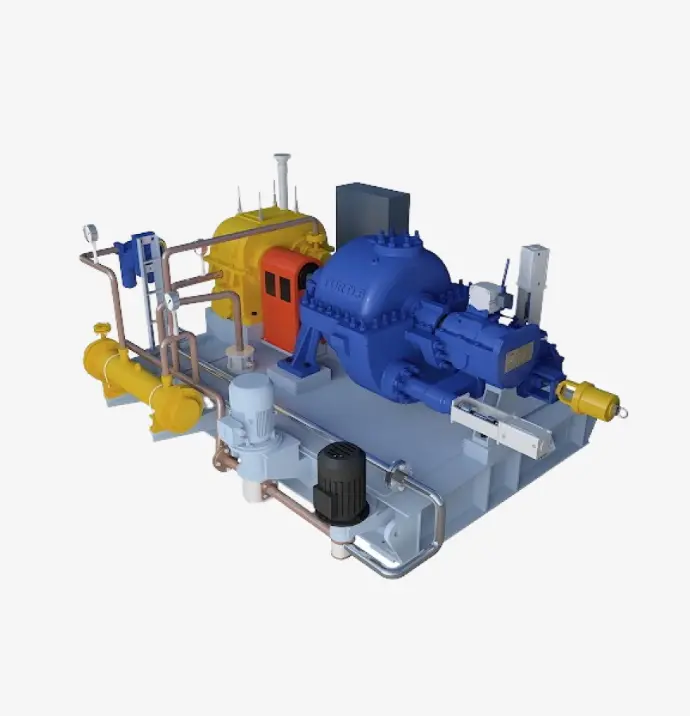

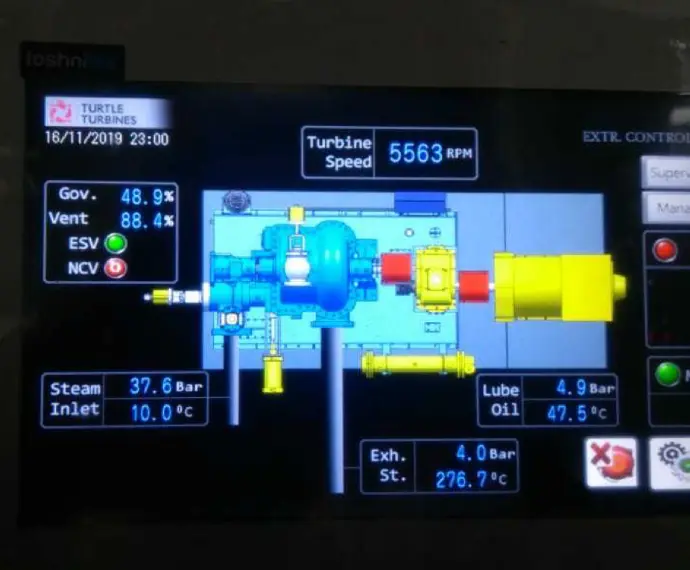

Extraction Back Pressure Steam Turbines

Extraction back pressure steam turbines are designed to extract multiple streams of steam at intermediate pressures while generating power. These extracted streams are then used for various industrial process heating applications at different temperatures, making them highly efficient and versatile in Cogeneration applications.

Versatile Cogeneration

Extraction Back Pressure Steam Turbines are versatile in terms of providing steam for process at two different pressures.

Reduce Cost

Extraction Back Pressure Steam Turbines drastically reduce Energy Cost thus reducing production cost

Extraction Back

Pressure Steam

Turbines

Extraction back pressure steam turbines are designed to extract multiple streams of steam at intermediate pressures while generating power. These extracted streams are then used for various industrial process heating applications at different temperatures, making them highly efficient and versatile in Cogeneration applications.

Versatile Cogeneration

Extraction Back Pressure Steam Turbines are versatile in terms of providing steam for process at two different pressures.

Reduce Cost

Extraction Back Pressure Steam Turbines drastically reduce Energy Cost thus reducing production cost

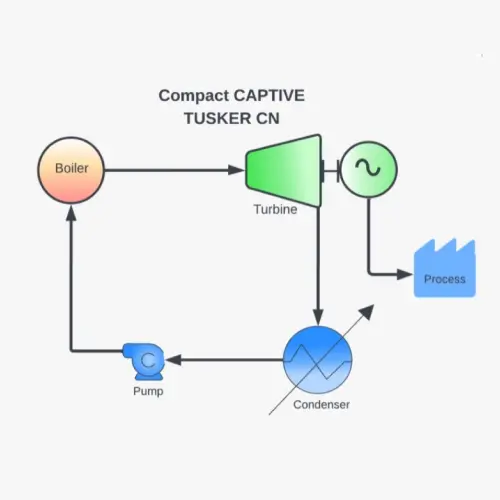

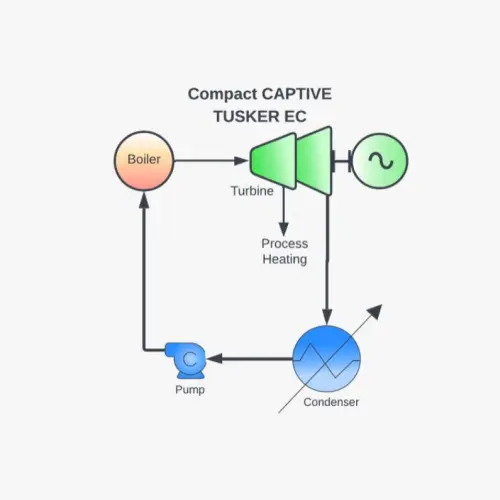

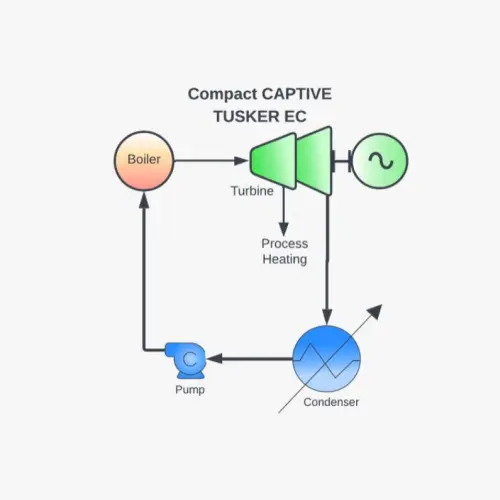

Condensing Steam Turbines

Condensing steam turbines are commonly used in captive power plants. They operate by expanding high-pressure steam through a series of blades to drive generators and produce electricity. Condensing steam turbines exhaust steam at vacuum, allowing it to be condensed into water, which is sent back to the boiler.

Condensing Steam Turbines

Condensing steam turbines are commonly used in captive power plants. They operate by expanding high-pressure steam through a series of blades to drive generators and produce electricity. Condensing steam turbines exhaust steam at vacuum, allowing it to be condensed into water, which is sent back to the boiler.

100% Grid Free

Condensing Turbines can allow plants and factories to be run at remote locations, 100% Grid Free.

Waste Heat to Energy

Industries generating Waste Heat, can use Condensing Steam Turbines to generate clean power.

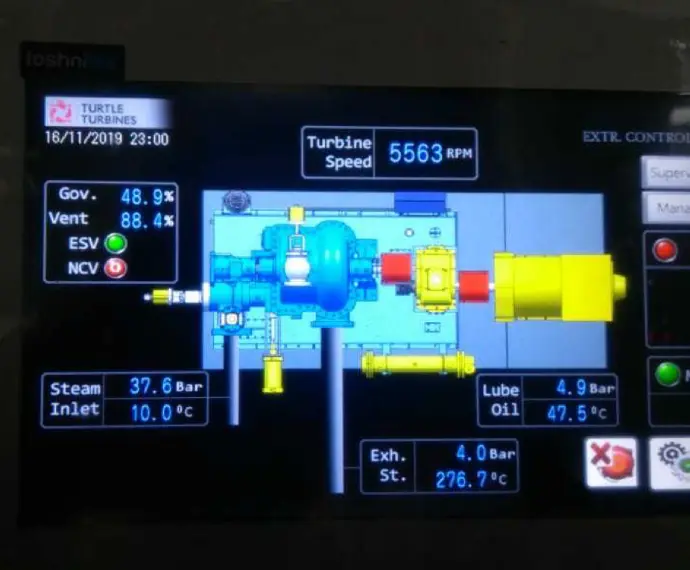

Extraction Condensing Steam Turbines

Extraction Condensing Steam Turbines Extraction condensing turbines are commonly employed in power plants where both electricity generation and steam extraction for industrial purposes are required. These turbines not only generate electricity by expanding high-pressure steam but also have one or more extraction points where steam is taken out at intermediate pressures for various industrial processes

Maximise Effificency

Extraction Condensing Steam Turbines maximise energy efficiency of the process plants Steam required for Heating is extracted from the intermediate stage.

Versatile Cogeneration

These are versatile in terms of providing the required heat and power thus blending the advantages of Cogen and Grid Free Power.

Steam Turbine Control Configurations based on Power Usage

Turtle Turbines manufactures a variety steam turbines controls in various configurations to meet different power consumption requirements in the Industries

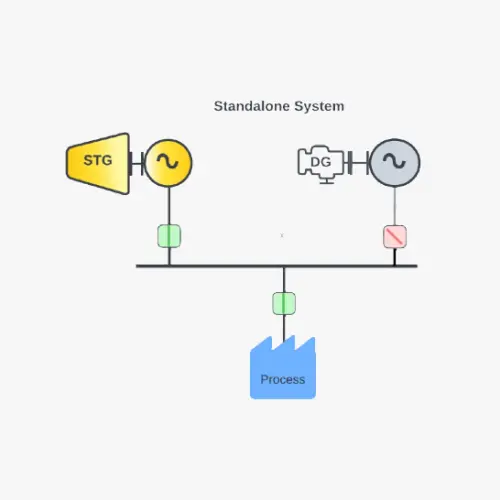

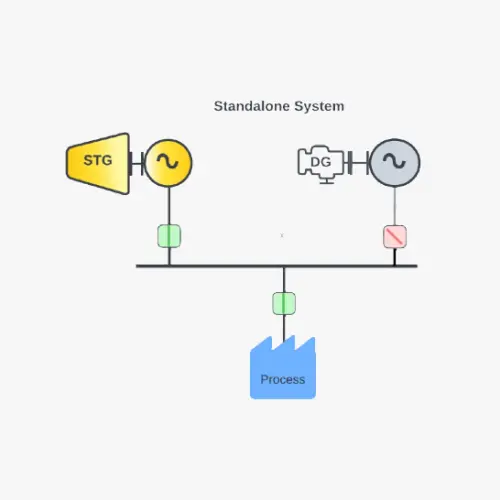

Stand Alone Steam Turbines

Stand Alone Steam Turbines refer to steam turbine systems that operate independently and are not integrated into a larger power grid. These turbines are typically used for specific applications where industries want to run their processes only on the power generated by the Steam Turbine. Stand Alone Steam Turbines are usually most suited to generate electricity for industries or communities in remote locations, isolated from the Grid.

Power Reliance

A community or Industry can generate all the power it needs. Complete reliance on the self generated power.

100% Grid Free

Factories or process plants can be conveniently and profitably located near the source of raw material or low cost labour. 100% Grid Free.

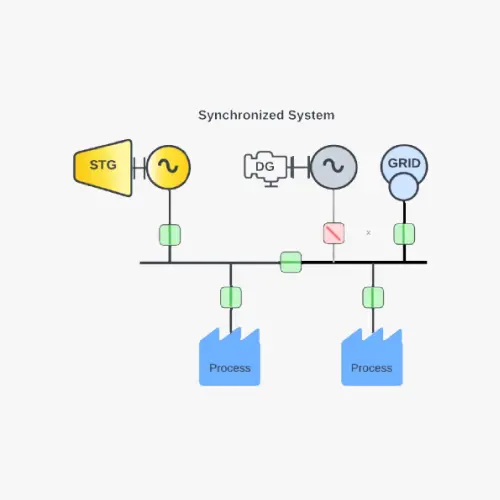

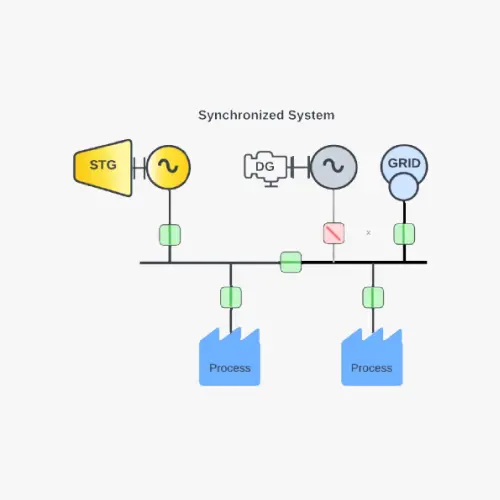

Grid Synchronised Steam Turbines

Grid Synchronised Steam Turbine systems are synchronised with the electrical grid. They produce electricity that matches the grid’s frequency and voltage, allowing seamless integration into the overall electrical power supply. These turbines are crucial components in power plants and process industries, ensuring stable and synchronized power generation for distribution across the electrical grid.

Maximise Effificency

Grid Synchronised Turbines maximise the utilisation of all the power generated thus enhancing efficiency.

Micro Grid Capable

Grid Synchronised Steam Turbines are compatible to work with Micro Grids. Can be synchronised with other power sources.

Extraction Condensing Steam Turbines

Extraction Condensing Steam Turbines Extraction condensing turbines are commonly employed in power plants where both electricity generation and steam extraction for industrial purposes are required. These turbines not only generate electricity by expanding high-pressure steam but also have one or more extraction points where steam is taken out at intermediate pressures for various industrial processes

Maximise Effificency

Extraction Condensing Steam Turbines maximise energy efficiency of the process plants Steam required for Heating is extracted from the intermediate stag.

Versatile Cogeneration

These are versatile in terms of providing the required heat and power thus blending the advantages of Cogen and Grid Free Power.

Steam Turbine Control Configurations based on Power Usage

Turtle Turbines manufactures a variety steam turbines controls in various configurations to meet different power consumption requirements in the Industries

Stand Alone Steam Turbines

Stand Alone Steam Turbines refer to steam turbine systems that operate independently and are not integrated into a larger power grid. These turbines are typically used for specific applications where industries want to run their processes only on the power generated by the Steam Turbine. Stand Alone Steam Turbines are usually most suited to generate electricity for industries or communities in remote locations, isolated from the Grid.

Power Reliance

A community or Industry can generate all the power it needs. Complete reliance on the self generated power.

100% Grid Free

Factories or process plants can be conveniently and profitably located near the source of raw material or low cost labour. 100% Grid Free.

Grid Synchronised Steam Turbines

Grid Synchronised Steam Turbine systems are synchronised with the electrical grid. They produce electricity that matches the grid’s frequency and voltage, allowing seamless integration into the overall electrical power supply. These turbines are crucial components in power plants and process industries, ensuring stable and synchronized power generation for distribution across the electrical grid.

Maximise Effificency

Grid Synchronised Turbines maximise the utilisation of all the power generated thus enhancing efficiency.

Micro Grid Capable

Grid Synchronised Steam Turbines are compatible to work with Micro Grids. Can be synchronised with other power sources.